2 stroke engine exhibit more simplicity by completing a full revolution in just two strokes in comparison to the four-stroke engine. These internal combustion engines have a two-stroke mechanism that involves the intake and the expansion stroke.

Two-stroke engines utilize an inlet port for both fresh mixture intake and exhaust gas expulsion instead of using separate inlet and exhaust valves like four-stroke engines. This direct injection of fuel and oil creates a unique loop where the incoming mixture pushes out any remaining exhaust gases.

Two-stroke engine basics.

Two-stroke engines, unlike their four-stroke counterparts, complete the combustion process in just two strokes of the piston. The 2 stroke engine lack valves which makes them simpler in design and operation.

In a two-stroke engine, the intake, compression, power, and exhaust strokes occur simultaneously.

- Intake stroke.

As the piston moves downward, it creates suction that draws in a mixture of fuel and air into the combustion chamber.

- Compression stroke.

The upward movement of the piston compresses the fuel-air mixture. At top dead center (TDC), the mixture is tightly compressed.

- Power stroke.

When the spark plug ignites the compressed mixture at TDC, it rapidly expands and forces the piston downward with considerable force. This translates into power for various applications such as motorcycles or chainsaws.

- Exhaust stroke.

Finally, as the piston reaches bottom dead center (BDC), it pushes out exhaust gases through an open port or valve.

Two-stroke engines offer advantages such as simplicity and higher power-to-weight ratios. However, they also have some drawbacks like higher emissions due to incomplete combustion.

These engines find widespread use in small recreational vehicles like dirt bikes and jet skis due to their lightweight nature and high power output. Additionally, they’re popular in handheld equipment like leaf blowers and hedge trimmers for their compactness and ease of use.

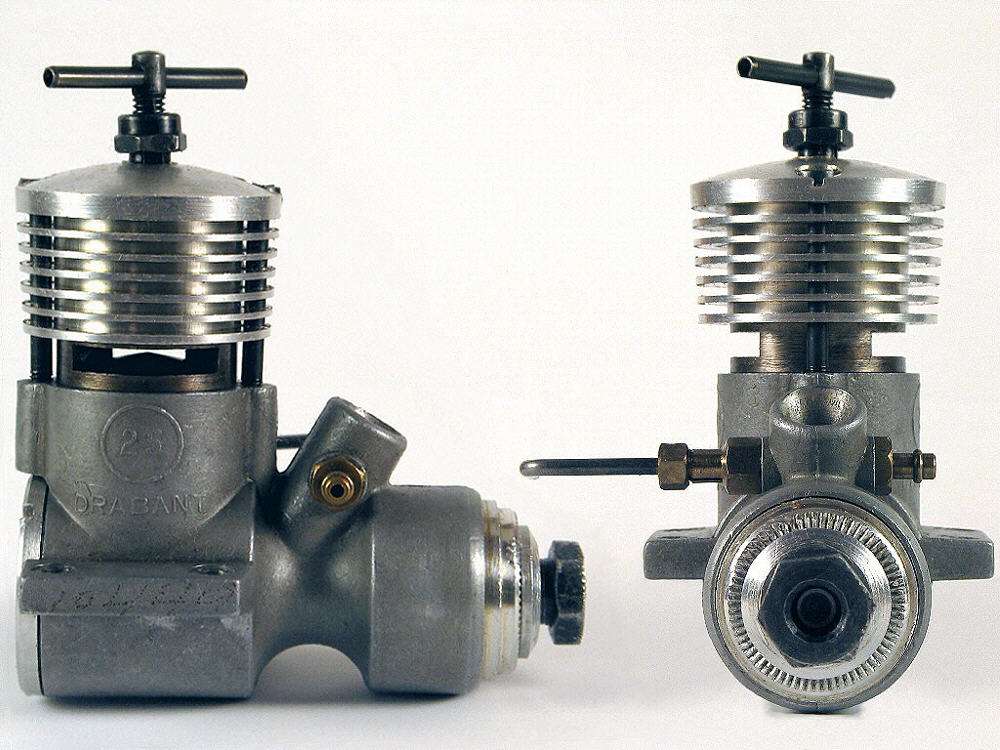

Components and construction of 2 stroke engines.

Two-stroke engines, also known as combustion engines, are widely used in various applications. These engines have a unique design and construction that sets them apart from their four-stroke counterparts.

- Common components.

Two-stroke engines consist of several essential parts such as the cylinder, piston, crankshaft, connecting rod, and spark plug. These components work together to facilitate the combustion process and convert fuel into mechanical energy.

- Intake control.

Some two-stroke engines incorporate reed valves or rotary valves for intake control. Reed valves allow the air-fuel mixture to flow in one direction while preventing backflow, optimizing engine performance. Rotary valves provide precise timing for the intake phase by controlling the opening and closing of ports.

- Lightweight and compact.

The construction of two-stroke engines emphasizes lightweight materials and compact designs. This characteristic makes them suitable for applications where space is limited or weight needs to be minimized without compromising power output.

Working mechanism of two-stroke engines.

Intake stroke, compression, ignition, power stroke, and exhaust stroke are some of the basic working mechanisms of two-stroke engines. These working mechanisms of 2 stroke engines involves a series of steps that enable the engine to function efficiently.

Two-stroke engines utilize a process called loop scavenging to enhance efficiency further. In this system, fresh air-fuel mixture enters through ports located on one side of the cylinder while simultaneously pushing out exhaust gases through another set of ports on opposite sides of the cylinder wall. This simultaneous intake and exhaust process creates better airflow and helps improve performance.

- Intake stroke.

During this stroke, the piston moves up and down within the cylinder, creating suction. As a result, the fuel-air mixture enters through ports or valves into the crankcase.

- Compression.

As the piston moves upward, it compresses the fuel-air mixture within the crankcase. This compression is crucial for generating power in the engine.

- Ignition.

Once compression occurs, a spark plug ignites the compressed fuel-air mixture. This ignition triggers combustion and initiates the power cycle.

- Power stroke.

The ignited fuel-air mixture expands rapidly, forcing the piston downward with considerable force. This downward motion is harnessed by connecting rods and a crankshaft to convert linear motion into rotary motion.

- Exhaust stroke.

After completing its power stroke, as the piston moves back up again, it pushes out any remaining exhaust gases from the cylinder through an exhaust port or valve.

Typical applications of two-stroke engines.

Two-stroke engines find their place in a wide range of applications, powering various machines and vehicle types. Whether it’s powering motorcycles or enabling outdoor maintenance tasks, two-stroke engines continue to be favored for their reliability and performance.

- Devices employing two-stroke engines.

Motorcycles, chainsaws, outboard motors, and dirt bikes are among the most common devices employing two-stroke engines. These compact powerhouses provide the necessary force to propel these vehicles forward.

- Lightweight design and high power-to-weight ratio.

In addition to larger equipment, two-stroke engines also find utility in smaller handheld tools like leaf blowers and trimmers. The lightweight design and high power-to-weight ratio make them ideal for quick yard work.

Jet skis and snowmobiles rely on these engines for thrilling adventures on water or snow-covered terrains. These versatile engines offer a practical solution across various industries due to their simplicity and efficiency.

Pros and cons of two-stroke engines.

Two-stroke engines have their fair share of advantages and disadvantages. 2-stroke engines offer advantages like simple design, high power output and lightweight, however, their disadvantages are high emissions and less fuel efficiency.

Pros of a 2-stroke engine.

Some of the pros of 2-stroke engines include their simple design, their lightweight, high power output and compact size.

- Simple design.

Two-stroke engines boast a straightforward design, making them easier to maintain and repair.

- Lightweight.

These engines are known for their lightweight construction, which is advantageous in various applications such as motorcycles and chainsaws.

- Higher power output.

Despite their smaller size, two-stroke engines deliver impressive power output, making them suitable for high-performance vehicles.

- Compact size.

Due to their compact design, these engines can fit into tight spaces where larger four-stroke engines may struggle.

Cons of a 2-stroke engine.

Some of the cons of 2-stroke engines are higher emissions, less fuel efficiency and their need for a mixture of oil and fuel for lubrication.

- Higher emissions.

One drawback of two-stroke engines is that they produce higher emissions compared to their four-stroke counterparts. That’s because they lack exhaust gas recirculation mechanisms which contribute to air pollution if not properly regulated.

- Less fuel-efficient.

Two-stroke engines tend to be less fuel-efficient than four-stroke engines. They consume more fuel due to the oil-fuel mixture required for lubrication.

- Require oil-fuel mixture for lubrication.

Unlike four-stroke engines that have separate oil compartments, two-strokes rely on a mixture of oil and fuel for lubrication. This adds complexity to the refueling process.

2-stroke engine vs 4-stroke engine.

When comparing the 2-stroke engine vs 4-stroke engine you need to consider power and efficiency, emissions, and fuel consumption requirements.

- Power and efficiency comparison.

Two-stroke engines, also known as 2-stroke engines, have a simpler design which gives them a higher power-to-weight ratio compared to four-stroke engines. This means that for the same weight, a two-stroke engine can produce more power than its four-stroke counterpart.

On the other hand, four-stroke engines are more fuel-efficient due to their combustion cycle. While two-strokes complete one combustion cycle every two strokes of the piston, four-strokes complete one combustion cycle every four strokes. This allows four-strokes to burn fuel more efficiently and deliver better fuel economy.

- Emissions considerations.

Two-stroke engines generally produce more pollutants than four-strokes. The incomplete combustion in two-strokes leads to higher emissions of unburned hydrocarbons and particulate matter. In contrast, the additional stroke in the cycle of a four-stroke engine allows for better combustion and reduced emissions.

2-stroke vs 4-stroke fuel and lubrication requirements.

Two-stroke engines and four-stroke engines differ in their fuel requirements and lubrication systems. Let’s take a closer look at the key differences:

- Two-strokes require a premixed fuel and oil.

The premixed fuel and oil in 2-stroke engines is for lubrication purposes since there is no separate oil system like in four-strokes. The fuel mixture in two-stroke engines consists of gasoline and oil combined together.

This mixture serves the dual purpose of providing fuel for combustion and lubricating the engine components. Without this premixed fuel-oil blend, two-stroke engines would lack proper lubrication, leading to damage or failure.

- Four-strokes use separate compartments for fuel (gasoline) and lubricating oil.

Unlike two-strokes, four-stroke engines have distinct compartments for fuel and oil. Gasoline is stored separately from the oil within the engine.

The engine draws only gasoline as its primary source of fuel during combustion. Lubricating oil is circulated through a dedicated system that keeps the engine running smoothly.

- Varying type of gasoline required for 2-strokes and 4-strokes.

Manufacturers typically recommend using high-quality, unleaded gasoline with an appropriate octane rating for optimal performance within the two-stroke engine. The 2-stroke engines often require a specific type of gasoline that suits their design and lubrication needs.

On the other hand, four-stroke engines usually have more flexibility. Regular unleaded gasoline commonly works well with these engines.

2-stroke vs 4-stroke power output and performance.

Two-strokes and four-strokes engines have distinct characteristics that affect their power output and performance.

- Power output per engine revolution.

Two-strokes, with their simplified design, are capable of producing more power per engine revolution compared to four-strokes. This is due to the fact that they complete a full combustion cycle in just two strokes of the piston, resulting in a higher power output.

On the other hand, four-stroke engines have a longer combustion cycle which leads to a smoother power delivery. This extended process allows for better fuel combustion and reduced vibrations, resulting in a more refined and consistent power output.

- Power-to-weight ratios.

Two-stroke engines are often favored in applications where high power-to-weight ratios are desired. Their lightweight construction combined with their ability to generate significant power makes them ideal for applications such as motorcycles, chainsaws, and small watercraft.

Choosing the right engine for your vehicle.

The choice between a two-stroke engine and a four-stroke engine depends on various factors such as the intended use of the vehicle and personal preferences. Here are some key points to consider:

For applications where high power-to-weight ratio is crucial, such as racing motorcycles or small recreational vehicles like jet skis, a two-stroke engine may be preferred.

If fuel efficiency is a priority or if you’re looking for an engine with lower emissions for environmental reasons, then a four-stroke engine would be a better choice.

The Otto cycle and two-stroke engine cycle.

The Otto cycle was named after Nikolaus Otto and is a theoretical four-stroke engine cycle that forms the basis for many internal combustion engines. However, things work a little differently.

In a two-stroke engine, there are only two strokes: the intake/compression stroke and the power/exhaust stroke. Unlike in a four-stroke engine where these strokes occur separately over two revolutions of the crankshaft, in a two-stroke engine both strokes happen simultaneously during one revolution.

- Intake/compression stroke.

The piston moves upwards, compressing the fuel-air mixture. As this happens, fresh air/fuel mixture enters through ports or valves. Compression increases as the piston reaches top dead center (TDC).

- Power/exhaust stroke.

At TDC, ignition occurs due to spark plugs or other ignition sources. The compressed mixture combusts rapidly, generating power.

This explosion pushes the piston downwards with force. As the piston descends, it uncovers exhaust ports or valves. The burnt gases exit through these ports or valves.

By combining these two strokes into one revolution of the crankshaft, two-stroke engines achieve more frequent power delivery compared to their four-stroke counterparts.

Two-stroke engine maintenance.

2-stroke engine maintenance involves cleaning or replacing spark plugs regularly maintaining the correct fuel-oil mixture ratio and regularly inspecting ports and valves to prevent carbon buildup. These activities differ slightly from the other car engine maintenance tasks.

- Cleaning or replacing spark plugs.

Regularly cleaning or replacing spark plugs is essential for optimal performance. Spark plugs play a crucial role in igniting the fuel-air mixture, so keeping them clean ensures efficient combustion. It’s recommended to inspect spark plugs every 25 hours of operation and replace them if necessary.

- Proper fuel-oil mixture ratios is crucial for lubrication.

Maintaining proper fuel-oil mixture ratios is crucial for lubrication purposes. Two-stroke engines require a specific blend of fuel and oil to ensure adequate lubrication of internal components. Using an incorrect ratio can lead to inadequate lubrication, causing excessive wear and potential engine damage. Always follow the manufacturer’s guidelines for the correct fuel-oil mixture ratio.

- Inspection of ports and valves.

Regular inspection of ports and valves helps prevent carbon buildup. Carbon deposits can accumulate over time, restricting airflow and reducing engine performance. Inspecting the ports and valves regularly allows you to identify any carbon buildup early on. Cleaning these components with appropriate solvents or tools can help restore optimal scavenging efficiency.

Keep your two-stroke engine running smoothly and prolong its lifespan by following these maintenance practices. Proper care and attention are key to reliable performance in two-stroke engines.