The automotive industry has advanced over time and these advancements have brought about the turbo technology. This is in an attempt to improve engine performance and power output.

Turbo technology helps with better air intake by incorporating forced induction which improves fuel consumption. Additionally, turbochargers are able to reduce the vehicle’s emissions.

Turbochargers provide a huge boost in power without any changes to the original equipment manufacturer OEM set-up.

Therefore, this boost in power is possible because the amount of power an engine produces depends on the amount of air it receives.

How turbo technology works.

The turbocharger in an internal combustion engine relies on the flow of exhaust gases in order to operate efficiently. This is what differentiates it from a supercharger.

Because the supercharger relies on mechanical power that comes from a belt on the engine’s crankshaft.

The turbocharger’s forced induction mechanism compresses the intake air into the engine. This increases the amount of air going into the combustion process.

In fact, it spins a turbine within the turbine chamber by using the exhaust fumes from the engine. The turbine chamber’s entrance is wide but it gets smaller progressively in order to ensure constant velocity.

Further, exhaust gasses exit the engine and enter the turbine housing entrance. This energy spins the turbine wheel.

Afterwards, it exits the turbo chamber through the outlet and flows into the exhaust system.

Further, on the opposite side of the turbocharger turbine wheel, you will find the compressor wheel housing. They are connected with a shaft.

The compressor housing gets air from outside or from the engine’s air intake set-up. This is a case where you have undertaken engine performance tuning to add intake mods.

But if that’s not the case, air still enters the compressor chamber through the use of spinning air compressor blades. The compressor’s housing entrance is small but it becomes larger progressively for better forced induction.

The purpose of forced induction is to increase the air mass intake of cylinders during every intake stroke. Afterwards this air goes through an intercooler which removes heat.

Components of a turbocharger.

Automotive technology has led to the adoption of turbocharged engines which are installed by manufacturers. This adoption is specifically common in high-performance engines that you will find on race tracks.

Turbochargers are a major racing technology. Manufacturers install turbochargers to boost performance for diesel engine cars.

It is important that you consider some of these components during the purchase of automotive aftermarket turbochargers.

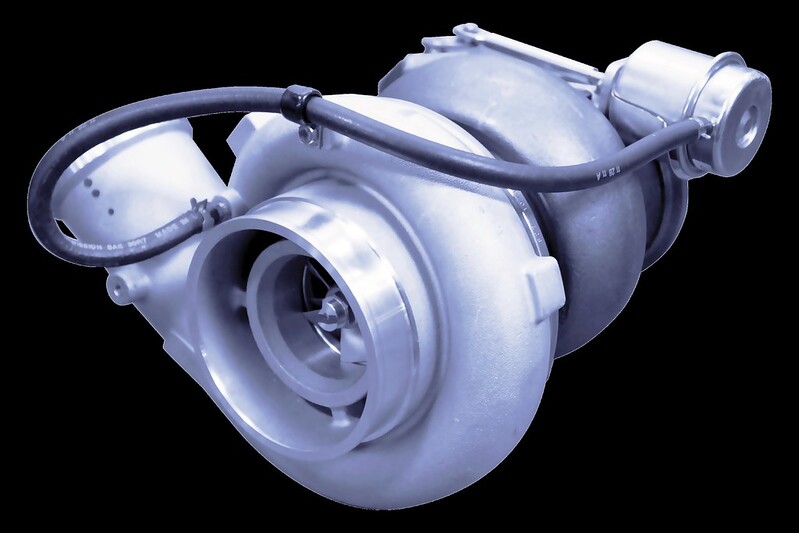

Turbochargers are made of two major component sections. These are;

- Compressor section.

- Turbine section.

But amongst these sections there are parts that aid in forced induction. For example;

- Turbine housing and wheel.

- Exhaust gas outlet.

- The compressor housing and wheel.

- Steel shaft / center housing / rotating assembly.

- Intercooler.

- Wastegates.

All these areas have been mentioned above in reference to how the turbocharger works.

We’ll discuss each one of them without following any particular order.

1. Turbine Wheel.

The role of this component part is to use heat and pressure to activate a rotational force. This possible because of the high pressure from exhaust gasses.

This pressure creates kinetic energy. Hence causing the turbine wheel to start rotating.

The size of the turbine wheel is an important consideration when choosing a turbocharger. Because a small turbine wheel will lead to engine chock.

This is one of the main causes of reduced engine power warning. Alternatively, a large turbine wheel will lead to engine lag as well as causing difficulties in attaining a desired performance boost.

2. Turbine housing.

This is an essential part of the turbine wheel. It is a big steel part that mounts on the exhaust manifold. Further, it is built with thick metal material for the purpose of withstanding heat and pressure.

Additionally, the turbine housing consists of a turbine foot and an outlet connection. In fact, the outlet connection goes to the downpipe.

Further, the turbine housing has a volute which acts as a path for the hot exhaust gas to pass to the turbine wheel. Afterwards, the gas goes to the outlet.

The main function of the turbine housing is to collect and transfer exhaust gasses.

3. Compressor wheel.

The compressor wheel starts rotating as a result of the turbine wheel’s rotation. It rotates at the same RPM as the turbine wheel.

It is the rotating turbine wheel that makes the shaft to start rotating. Afterwards, the spinning shaft causes the compressor wheel to start rotating.

As the engine and turbine wheel RPM increases, so does the compressor wheel’s RPM. Therefore this rotation results to fresh air compression towards the throttle body intake tube.

4. Steel shaft / Center housing / Rotating assembly.

It acts as a connection between the compressor housing and turbine wheel housing. It gets rotation momentum when the turbine wheel starts rotating.

Afterwards, this rotating shaft causes the compressor wheel to start rotating. Its material is strong enough to withstand heat and stress from both the turbine wheel and compressor wheel.

Another essential role that it plays includes the support and lubrication of the turbocharger bearings. The turbocharger bearing is much more effective during high RPM in comparison to the camshaft bearing.

The turbocharger bearings tend to wear out due to shaft movement, engine oil condition and axial load.

5. Intercooler.

An intercooler is essential in turbochargers because of the fact that an increase in air pressure results to an increase in heat. The intercooler will eliminate heat from air before it goes into the air intake manifold.

Because air under pressure creates heat, the intercooler is simply a heat exchanger. It works under the same principal as the radiator.

Types of intercoolers.

The engine performance market has two main types of intercoolers.

a] Air to air intercooler.

They are the most common type because of their high availability as well as affordability. It is made up of fins and interconnected pipes.

Therefore, it functions by passing the hot air from the compressor through the tubes. Meanwhile, ambient air passes over the intercooler pipes and thin fins which brings about a cooling effect.

b] Air to water intercooler.

It operates through the same principle as the air to air intercooler. However, the difference comes about because chilled water takes the place of ambient air.

The downside of this type of intercooler is that the water eventually heats up. Hence reducing the efficiency of the cooling effect. Therefore the water will have to undergo cooling every time it heats up.

This will negatively affect power output. Further, it will lead to a lot of time wastage.

6. Wastegates.

Wastegates have an inlet and outlet valve. Further, they have a diaphragm which controls when these valves open and close.

Additionally, this diaphragm begins to close when the turbine wheel RPM increases.

Turbocharger systems rely on wastegates to control boost and engine power output. Because without the wastegates, exhaust fumes would be uncontrollably directed towards the turbine wheel before exiting to the downpipe.

As a result of this, boost keeps rising uncontrollably until the throttle closes or the turbine wheel reaches a choke point. This will cause damage to the engine.

Wastegates are mounted before the turbine wheel housing in order to receive the exhaust fumes. This allows for control of the percentage amount of exhaust fumes.

Hence regulating the turbine wheel RPM.

Turbocharger maintenance tips.

A fully functional turbo charger is an important car engine part. In order to avoid any engine trouble, there are a number of maintenance activities that you need to undertake for the turbocharger.

As we have seen above, the turbocharger could malfunction and cause damage to the engine. The intervals under which you should observe regular maintenance depend on the manufacturer’s recommendations.

1. Oil change.

Fresh and sufficient oil is important for proper turbocharger and engine functionality. There are a number of functions that oil plays within the engine. For example, lubrication.

Undertaking oil change depends on the driving environment and manufacturer recommendations. After undertaking an oil change, also consider installing a new oil filter.

Oil flows to the turbo to lubricate the moving parts. Without which these parts will become worn out at a much higher rate.

Further, ensure that you inspect the oil pipes that facilitate its supply.

2. Air filter.

Because the compressor gets air into the intake manifold, the air needs to be clean. The function of the air filter is cleaning air that goes into the engine.

A dirty air filter chokes the amount of air that can be accessed by the engine’s turbocharger. Further, it means that the air going into the engine is full of contaminants.

These contaminants could harm the engine and clog the throttle valve. Hence preventing proper power output during accleration.

3. Warm-up the engine.

Warming up the engine after parking for prolonged hours is very important. You can do so by sitting inside a car whose engine is running or by driving at a low speed first before flooring the accelerator.

This gives oil time to circulate through out the engine parts including the turbocharger automotive technology.

4. Intake and exhaust good practices.

Pay attention to the sounds that come from the engine when you’re driving. Because you may notice a whistling sound.

This could mean that there are compressor or turbine leaks. These leaks make the turbo to work harder than it should.

Perform regular inspections of these areas so as to ensure everything is in order. Ensure that you look at the turbine and compressor wheels.

If they are worn out it means that air isn’t spreading properly through out their surface. Monitor the exhaust manifold and wastegate to ensure there are no leaks.

Because these leaks will reduce air pressure and this will reduce power output.