Hydraulic brake systems employ fluid pressure to transmit force from your input as a driver to the brakes, ensuring efficient and reliable braking. The hydraulic brake system consists of various components such as the master cylinder, brake lines, caliper pistons, and brake pads.

When you press the brake pedal, the master cylinder exerts fluid pressure through the hydraulic lines to activate the caliper pistons. These pistons then squeeze the brake pads against the rotor or drum, creating friction and slowing down or stopping your vehicle.

Modern vehicles come to a halt quickly and effectively thanks to hydraulics and fluid pressure. This innovation in braking technology has significantly improved road safety by reducing stopping distances and enhancing control over vehicles during emergency situations.

Types of hydraulic brake systems.

There are two main types of hydraulic brake systems are the drum brakes and disc brakes. When choosing between these various types of hydraulic brake systems, it is important to consider factors such as vehicle type, intended use, budget, and personal preferences.

Whether you opt for drum or disc brakes, ensuring regular car brake system maintenance and proper adjustment is crucial for optimal braking performance.

1. Drum brakes.

Drum brakes utilize friction between shoes and a rotating drum. They are commonly found in older vehicles and certain heavy-duty applications.

Some of the advantages of drum brakes are the fact that they’re a cost-effective option, they have a simpler design and they can withstand higher temperatures without fading.

However, some of the disadvantages of drum brakes are the fact that they’re prone to overheating under heavy use, less effective at dissipating heat compared to disc brakes and they’re more difficult to service and maintain.

2. Disc brakes.

Disc brakes, on the other hand, rely on friction between pads and a rotating disc. They are widely used in modern vehicles due to their superior performance and reliability.

Some of the advantages of disc brakes are the fact that they have better stopping power and shorter braking distances, improved heat dissipation, reducing the risk of brake fade and they offer easier maintenance and replacement of brake pads.

Alternatively, some of the disadvantages of disc brakes are their higher cost compared to drum brakes and they’re susceptible to rusting in certain conditions.

Differences between drum and disc hydraulic brakes.

Drum brakes, though less expensive than disc brakes, have lower heat dissipation capabilities. On the other hand, disc brakes offer superior cooling properties due to their exposed design, making them ideal for high-performance applications.

In terms of usage, drum brakes are commonly found on rear wheels, while disc brakes are often installed on front wheels to enhance stopping power.

1. Drum brakes.

They’re the less expensive option, they offer lower heat dissipation capabilities and they’re commonly used in rear wheels. Some of the components of drum brakes include drum, rear caliper, and wheel cylinder

2. Disc brakes.

The disc brakes offer better cooling properties, secondly, they’re suitable for high-performance applications and they’re often found on front wheels. Some of the components of disc brakes include disc, piston calipers.

It ultimately depends on your specific needs and preferences. If cost is a major factor and you prioritize affordability over performance, drum brakes may be the way to go.

However, if you require better cooling abilities or plan to use your vehicle for high-performance activities like mountain biking with disc brake-equipped bikes, then opting for disc brakes would be more suitable.

Advantages of hydraulic brakes.

Exceptional stopping power and reliable performance in extreme conditions are some of the advantages of hydraulic brakes. Hydraulic brakes, also known as hydraulic braking systems, offer a range of advantages that make them highly desirable for vehicles.

- Excellent stopping power.

One of the key advantages of hydraulic brakes is their ability to provide outstanding stopping power. This means that when you hit the brake pedal, your vehicle responds quickly and effectively, allowing for shorter braking distances. Whether you’re driving at high speeds or navigating through congested traffic, hydraulic brakes ensure that you can come to a stop swiftly and safely.

- Consistent and reliable performance.

Hydraulic braking systems are designed to deliver consistent and reliable performance even under extreme conditions. Unlike other types of brakes that may experience fading or reduced effectiveness over time, hydraulic brakes maintain their efficiency throughout their lifespan. This reliability gives drivers peace of mind knowing they can depend on their brakes when it matters most.

- Modulate braking force.

Another advantage offered by hydraulic systems is their ability to modulate braking force. This means that drivers can easily control and adjust the amount of pressure applied to the brake pedal based on specific driving scenarios. Whether it’s gently slowing down for a turn or applying maximum force during an emergency stop, hydraulic brakes allow for precise modulation to suit different situations.

Disadvantages of hydraulic brakes.

Hydraulic brake systems have their fair share of drawbacks like complexity and cost, their need for regular maintenance and their vulnerability to leaks. These disadvantages should be considered before opting for this type of braking mechanism.

- Complexity and cost.

Compared to mechanical brake systems, hydraulic brakes can be more complex and expensive to manufacture. This complexity arises from the need for additional components such as master cylinders, hydraulic lines, and calipers. As a result, the overall cost of installation and maintenance tends to be higher.

- Regular maintenance.

To ensure optimal performance, hydraulic brakes require regular maintenance. This includes periodic fluid checks and replacements. Over time, brake fluid can become contaminated or depleted, affecting the system’s efficiency and responsiveness. Neglecting these maintenance tasks can lead to diminished braking power or even complete failure.

- Vulnerability to leaks.

One significant disadvantage of hydraulic brakes is their vulnerability to leaks. If a leak occurs in the system, either due to damaged components or faulty connections, it can compromise the effectiveness of the brakes. In such situations, braking performance may deteriorate rapidly or fail altogether, posing a safety risk.

While hydraulic brakes offer advantages like improved stopping power and better modulation compared to mechanical alternatives, it is essential to acknowledge these downsides as well.

The complexity and cost involved in manufacturing them along with the need for regular maintenance make them less appealing for some individuals or applications where simplicity and lower costs are prioritized.

Moreover, their susceptibility to leaks further emphasizes the importance of proper upkeep and prompt repairs when issues arise within the system.

Components of hydraulic braking systems.

The master cylinder, brake lines, caliper, wheel cylinders, brake pads or shoes are some of the components of hydraulic braking systems.

Hydraulic braking systems play a crucial role in ensuring the safety and control of vehicles on the road. Let’s delve into the components and functionality of these essential systems.

Hydraulic braking systems consist of several key components that work together to provide reliable stopping power. These include:

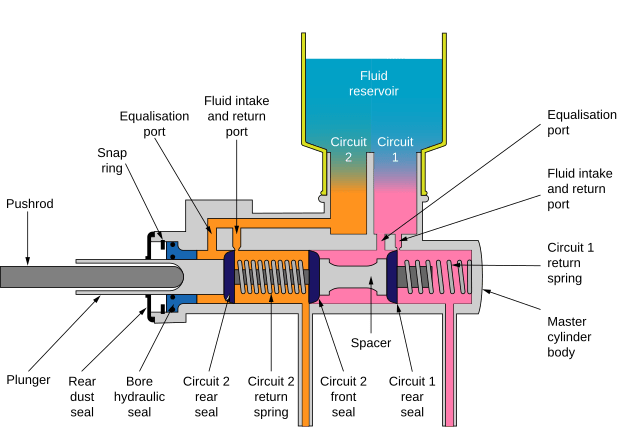

- Master cylinder.

The master cylinder converts mechanical force, applied by the driver through the brake pedal, into hydraulic pressure.

- Brake lines.

These sturdy tubes transport hydraulic fluid from the master cylinder to the brake units.

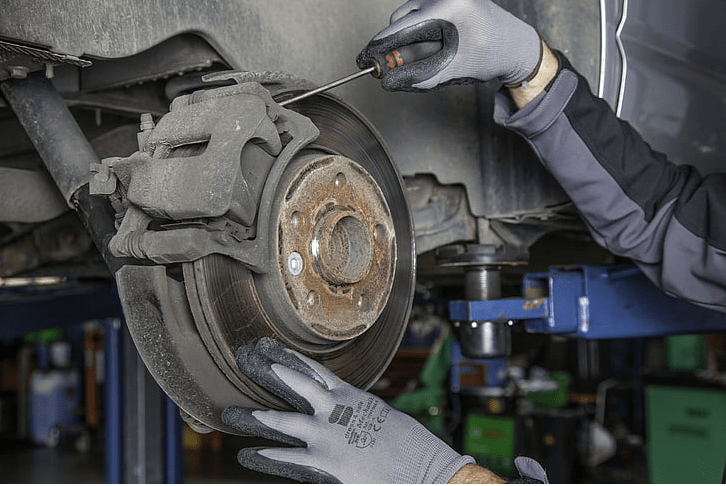

- Caliper.

Found in disc brake systems, calipers use hydraulic pressure to squeeze brake pads against a rotor, creating friction and slowing down the vehicle.

- Wheel cylinders.

Typically present in drum brake systems, wheel cylinders exert pressure on brake shoes, causing them to press against a rotating drum.

- Brake pads or shoes.

Brake pads in disc brakes press against the rotor to help minimize the speed of your vehicle. This is the similar function that is played by the brake shoes in drum brakes. Both brake pads and shoes are friction materials come into direct contact with either the rotor or drum when brakes are applied.

How car hydraulic brakes work: Functionality.

When you press the brake pedal, it pushes a piston inside the master cylinder which forces hydraulic fluid through the brake lines. This increase in fluid pressure causes pistons in calipers (or wheel cylinders) to move outward and apply pressure on the brake pads (or shoes).

The resulting friction between pads (or shoes) and rotors (or drums) slows down or stops your vehicle. Pressing the brake pedal activates the hydraulic system.

- The master cylinder contains a piston that is pushed by the force of your foot.

- As the piston moves, it compresses the hydraulic fluid in the master cylinder.

- The compressed fluid then travels through brake lines to reach each wheel.

- At each wheel, there are calipers or wheel cylinders that house pistons.

- The increased fluid pressure causes these pistons to extend outward.

- The pistons push against brake pads or shoes, creating friction with rotors or drums respectively.

- This friction slows down or stops the rotation of wheels, thus slowing down or halting your vehicle.

Hydraulic vs. mechanical braking.

The control over braking force, stopping power and higher clamping forces, physical strain levels and friction materials used are the areas of comparing hydraulic vs. mechanical braking.

- Control over braking force.

Hydraulic braking systems, unlike their mechanical counterparts, offer precise control over braking force by utilizing hydraulic pressure instead of cables or levers. This advanced technology allows for a more efficient and effective braking experience.

- Stopping power and higher clamping forces.

One key advantage of hydraulic brakes is their ability to generate higher clamping forces compared to mechanical systems. This increased stopping power ensures a quicker response when it matters most.

- Physical strain levels.

In addition to their superior performance, hydraulic brakes require less effort from drivers due to their power-assisted nature. By harnessing the power of hydraulic pressure, these brakes make it easier for drivers to apply the necessary force without straining themselves.

- Friction materials used.

Both hydraulic and mechanical brake systems rely on specific materials such as rubber or Kevlar for optimal performance. These friction materials play a crucial role in creating the necessary grip between the brake pads and rotors or drums.

Common hydraulic brake system brake issues.

Worn-out brake pads or shoes, brake fluid leaks and air bubbles in brake lines are some of the common hydraulic brake system brake issues.

Brake failure can be a terrifying experience for any driver. To ensure your safety on the road, it’s crucial to be aware of common hydraulic brake system issues that may compromise your braking performance. Let’s take a closer look at some of these issues and their potential impact.

1. Brake fluid leaks.

One of the primary culprits behind reduced braking performance is brake fluid leaks. When there is a leak in the hydraulic system, it can lead to a loss of hydraulic pressure, resulting in ineffective brakes. Keep an eye out for signs such as puddles of fluid beneath your vehicle or a low brake fluid level in the reservoir. If you notice any leaks, it’s essential to address them promptly to maintain optimal braking power.

2. Air bubbles in brake lines

Another issue that can hamper your braking efficiency is the presence of air bubbles in the brake lines. When air gets trapped within the system, it creates a spongy brake pedal feel and reduces overall stopping power. Bleeding the brake lines to remove air pockets is necessary to restore proper functionality. If you find yourself with a mushy or unresponsive brake pedal, consider having your brake lines bled by a professional mechanic.

3. Worn-out brake pads or shoes.

Over time, brake pads and shoes wear down due to friction against rotors or drums respectively. It’s important to regularly inspect them for signs of excessive wear or thinning material. If neglected, worn-out brake pads or shoes can compromise your ability to stop effectively and increase stopping distances.

Importance of proper brake fluid for hydraulic brakes.

Brake fluid is a vital component in the proper functioning of hydraulic brakes. It serves the crucial role of transmitting hydraulic pressure within the braking system. To ensure optimal operation and longevity of hydraulic brakes, it is essential to use the correct type of brake fluid recommended by the vehicle manufacturer.

Regular inspection and replacement of brake fluid are necessary to prevent moisture absorption, corrosion, and potential brake failure. Moisture can enter the braking system through worn-out seals or by permeating through rubber hoses over time. This moisture can lead to a decrease in boiling point, causing vapor lock and reduced braking performance.

Using the right brake fluid specified by the manufacturer ensures compatibility with internal components, such as seals and rubber parts. Different types of brake fluids are available, including DOT (Department of Transportation) fluids and mineral oil-based fluids. It is crucial to adhere to the recommended fluid type for your specific vehicle.

Failure to maintain proper brake fluid levels or using an incompatible fluid can result in compromised braking performance, loss of control, or even complete brake failure. Therefore, it is imperative to follow manufacturer guidelines regarding inspection intervals and replacement schedules.

Brake fluid change intervals.

Brake fluid is an essential component of any car brake system. To ensure optimal braking performance and extend the lifespan of your hydraulic brake components, it’s important to replace the brake fluid at regular intervals.

- Follow manufacturer’s recommendations.

It is crucial to adhere to the vehicle manufacturer’s recommended brake fluid change intervals. These recommendations may vary depending on the make and model of your vehicle. Check your owner’s manual or consult with a trusted mechanic to determine the specific interval for your car.

- General guideline.

As a general guideline, it is recommended to change the brake fluid every two years. This timeframe helps prevent moisture absorption in the fluid, which can lead to a decrease in its boiling point over time.

- Moisture absorption and fluid fade.

Brake fluid has hygroscopic properties, meaning it absorbs moisture from the air over time. This moisture accumulation can result in reduced braking performance due to a phenomenon known as “fluid fade.” When brake fluid reaches its boiling point, it can cause vapor bubbles that compromise braking effectiveness under high temperatures.

- Optimal braking performance.

Regularly changing the brake fluid helps maintain optimal braking performance by ensuring that there are no contaminants or moisture present that could affect its ability to transmit force from the pedal to the brakes.

- Extended lifespan of components.

By replacing the brake fluid at recommended intervals, you can help extend the lifespan of various hydraulic brake components such as master cylinders, calipers, and wheel cylinders. Fresh brake fluid minimizes corrosion and wear on these components, contributing to their longevity.