Emission control systems reducing emissions by regulating harmful pollutants released by vehicles and improving air quality. Hence, ensuring a cleaner and healthier environment for all.

The emission control systems are essential for maintaining optimal performance while complying with emission standards. By effectively controlling the amount of pollutants released into the atmosphere, these systems contribute to a greener future.

Emission control systems have evolved over time from injection systems to conventional silencers in order to meet stringent regulations and lower emission levels.

Key takeaways on emission control systems.

These systems employ different technologies such as catalytic converters, exhaust gas recirculation (EGR), and evaporative emission control to minimize emissions.

Regular maintenance and ensuring proper functioning of emission control systems are essential to optimize vehicle performance and minimize environmental impact.

Catalytic converters play a significant role in reducing emissions by converting harmful gases into less harmful substances through chemical reactions.

Exhaust gas recirculation (EGR) helps lower nitrogen oxide emissions by redirecting a portion of exhaust gases back into the combustion chamber, resulting in lower combustion temperatures.

Evaporative emission control prevents the release of volatile organic compounds (VOCs) from fuel evaporation, reducing air pollution.

Cars equipped with efficient emission control systems not only contribute to cleaner air but also comply with environmental regulations.

The durability of emission control systems ensures their long-lasting effectiveness in reducing pollutants over time.

Mile durability refers to the ability of these systems to maintain their efficiency throughout the vehicle’s lifespan, providing continuous emission reduction benefits.

What is an emission control system?

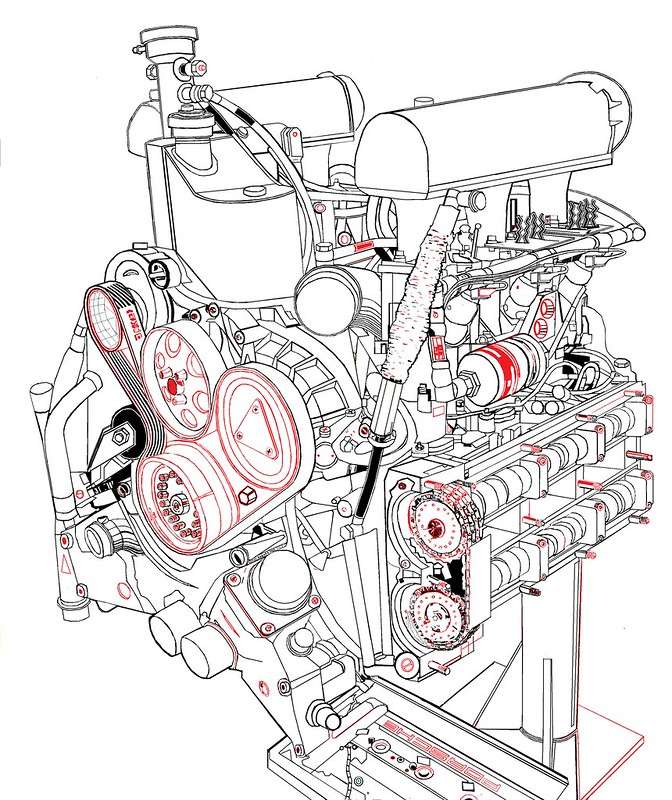

An emission control system consists of various parts such as catalytic converters, oxygen sensors, PCV valves, and mufflers. It is a crucial component in vehicles that aims to reduce harmful emissions. The primary goal of this system is to convert or trap pollutants before they are released into the atmosphere.

The emission control system plays a vital role in minimizing the impact of vehicle emissions on air quality and human health. It contributes to a cleaner and healthier environment by effectively reducing harmful substances.

Components of an emission control system.

Mufflers, PCV valves, oxygen sensors and catalytic converters are the main components of an emission control system.

- Catalytic converters.

These devices help convert toxic gases produced during combustion into less harmful substances.

- Oxygen sensors.

They monitor the amount of oxygen present in the exhaust gases, allowing the engine control unit (ECU) to adjust fuel-air mixture for optimal combustion efficiency.

- PCV valves.

Positive Crankcase Ventilation (PCV) valves regulate the flow of gases from the engine’s crankcase back into the intake manifold, preventing harmful fumes from escaping into the atmosphere.

- Mufflers.

Apart from reducing noise levels, mufflers also play a role in controlling emissions by minimizing backpressure and optimizing exhaust flow.

By combining these components and their functions, emission control systems actively contribute to reducing pollution caused by vehicle emissions.

Emission control system parts.

Common emission control system parts include catalytic converters, oxygen sensors, mufflers, PCV valves, and fuel injectors.

A fully functional emission control system facilitates proper flow of the vehicle’s engine exhaust back pressure. It consists of various components that work together to reduce harmful emissions. Let’s take a closer look at the key parts involved:

1. Catalytic converters.

These devices play a vital role in converting harmful gases into less harmful substances through chemical reactions. They help to reduce pollutants such as carbon monoxide, nitrogen oxides, and hydrocarbons.

2. Oxygen sensors.

Oxygen sensors monitor the amount of oxygen present in the exhaust gases. By providing feedback to the engine control unit (ECU), they help optimize fuel-air mixture ratios for better combustion efficiency and lower emissions.

3. Mufflers.

Mufflers primarily serve to reduce noise produced by the exhaust system. However, they also contribute to emission control by minimizing backpressure on the engine and improving overall exhaust flow.

3. PCV Valve (Positive Crankcase Ventilation Valve).

The PCV valve is an important component of the vehicle’s emissions control system. Its main function is to regulate the release of gases (blow-by gases) from the crankcase back into the intake manifold to be burned again in the combustion process.

This helps reduce the emission of harmful gases into the atmosphere. The PCV system prevents the buildup of pressure within the crankcase, which can cause oil leaks and engine damage, while also ensuring that unburned fuel and oil vapors are recycled instead of being released directly into the environment.

4. Fuel injectors.

Fuel injectors are critical components of the fuel delivery system and play a vital role in controlling emissions. They are responsible for delivering precise amounts of fuel into the engine’s combustion chambers at the correct time and in the correct spray pattern for optimal combustion.

By ensuring an efficient and complete burn of the fuel, fuel injectors help to reduce the emission of unburned hydrocarbons and other pollutants. Modern fuel injectors are electronically controlled, allowing for precise adjustments based on the engine’s operating conditions, further enhancing fuel efficiency and reducing emissions.

Types of emission control systems.

Three main types of emission control systems used in vehicles are three-way catalysts (TWC), lean NOx traps (LNT) and diesel particulate filters (DPF). Each type of emission control system serves a unique purpose in curbing pollution from vehicle exhausts.

TWCs address multiple pollutants simultaneously, while LNTs focus on reducing nitrogen oxides in lean-burn gasoline engines. On the other hand, DPFs specifically target the harmful soot particles produced by diesel engines.

1. Three-way catalysts (TWC).

TWCs are designed to reduce carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbon (HC) emissions simultaneously. They play a crucial role in minimizing the harmful pollutants released into the atmosphere.

2. Lean NOx traps (LNT).

LNTs specifically target nitrogen oxide reduction in lean-burn gasoline engines. By trapping and converting NOx, these systems aid in reducing emissions from this particular type of engine, contributing to cleaner air quality.

3. Diesel particulate filters (DPF).

DPFs are employed to capture soot particles emitted by diesel engines. These filters effectively trap and remove the fine particles that can be detrimental to both human health and the environment.

By employing these emission control systems, automotive manufacturers strive to minimize their vehicles’ impact on air quality and promote environmentally friendly transportation options.

Advanced catalyst system and selective catalyst reduction (SCR).

The role of advanced catalyst systems like selective catalytic reduction (SCR) in emission control is to utilize a chemical reaction to convert harmful nitrogen oxides into harmless nitrogen and water vapor.

Emission control systems are crucial for reducing the release of harmful pollutants like carbon monoxide, nitrogen oxides, and hydrocarbons in cars.

1. Selective catalytic reduction (SCR).

SCR systems employ a reduction catalyst, typically made of metals like platinum, to facilitate the conversion process. To optimize the efficiency of SCR, catalytic reactors with ceramic honeycomb structures are commonly used.

Diesel vehicles often rely on SCR technology to meet stringent emission standards set by regulatory bodies.

2. Ad-Blue or DEF.

The conversion process in SCR is facilitated by injecting a urea-based solution called Ad-Blue or DEF into the exhaust stream.

When AdBlue or DEF comes into contact with the hot exhaust gases, it reacts with nitrogen oxides, breaking them down into nitrogen and water vapor through reduction reactions.

The use of an oxidation catalyst further enhances the purification process by converting carbon monoxide and unburned hydrocarbons into carbon dioxide and water vapor. The high temperature within the combustion engine ensures that these reactions occur efficiently.

Exhaust gas recirculation (EGR) and its role in emission control.

Redirecting exhaust gases, lowering combustion temperatures and improving engine efficiency are the roles of exhaust gas recirculation (EGR) in emission control.

The exhaust gas recirculation (EGR) system is an essential component in emission control systems for gasoline and diesel engines. It effectively reduces nitrogen oxide emissions by redirecting a portion of exhaust gases back into the engine’s combustion chamber.

By diluting the air-fuel mixture, EGR lowers combustion temperatures, which in turn reduces the formation of harmful pollutants. This process plays a crucial role in controlling exhaust emissions and ensuring compliance with environmental regulations.

1. EGR redirects exhaust gases.

The system channels a specific amount of exhaust gases back into the engine’s intake manifold, where they mix with fresh air and fuel before entering the combustion chamber. This helps to lower peak temperatures during combustion.

2. Lowering combustion temperatures.

By reducing peak temperatures, EGR prevents excessive formation of nitrogen oxides (NOx), which are major contributors to air pollution. The diluted air-fuel mixture also helps prevent detonation or knocking that can damage the engine.

3. Improving engine efficiency.

Although EGR slightly decreases the overall efficiency of an engine, it significantly improves its thermal efficiency by reducing heat losses through lower combustion temperatures. This leads to better fuel economy and performance.

Evaporative emission control: Managing harmful vapors.

Evaporative emission control systems consist of various components that work together to minimize the release of harmful gases into the air. These components include charcoal canisters, purge valves, and fuel tank caps equipped with pressure relief valves.

Evaporative emission control systems play a crucial role in preventing the release of harmful fuel vapors into the atmosphere. Significantly reduce air pollution and its detrimental effects on our environment by effectively managing these vapors which are released at the exhaust manifold.

1. Charcoal canisters.

Charcoal canisters act as filters, trapping unburned hydrocarbons from the fuel tank before they are released into the atmosphere. This helps prevent smog formation and reduces the emission of volatile organic compounds (VOCs).

2. Purge valves.

Purge valves play a vital role in maintaining proper pressure within the fuel system. They ensure that excess vapors are directed back to the combustion chamber for burning rather than being released into the environment.

3. Fuel tank caps with pressure relief valves.

Vehicle fuel tank is covered by caps with pressure relief valves help regulate pressure changes within fuel tanks caused by temperature fluctuations or altitude variations. This prevents excessive vapor leakage and ensures efficient operation of the evaporative emission control system.

Understanding how emission control systems work.

Oxidation, reduction, adsorption, and dilution are some of the methods through which emission control systems work. Emission control systems reduce harmful pollutants released into the environment. These systems operate through various mechanisms to effectively mitigate emissions.

- Oxidation.

One mechanism employed by emission control systems is oxidation, which involves converting harmful gases into less toxic substances through chemical reactions.

- Reduction.

Another method used is reduction, where pollutants are chemically transformed into less harmful compounds.

- Adsorption.

Emission control systems also utilize adsorption, a process that involves capturing and retaining pollutants on surfaces such as activated carbon or zeolite.

- Dilution.

Dilution is an essential mechanism where exhaust gases are mixed with clean air to reduce their concentration and overall impact on the environment.

Catalytic converters and precious metals.

Catalytic converters play a vital role in emission control systems by facilitating chemical reactions that convert harmful emissions into less detrimental substances. These devices contain precious metals like platinum and palladium, acting as catalysts to speed up these reactions.

Oxygen sensors for optimal fuel-air mixture regulation.

To ensure efficient combustion and minimize emissions, oxygen sensors are utilized within emission control systems. These sensors monitor oxygen levels in exhaust gases, providing valuable feedback for regulating the fuel-air mixture ratio.

Importance of emission control systems.

The importance of emission control systems is in reducing air pollution and safeguarding human health from harmful pollutants emitted by vehicles. These systems help maintain clean air quality standards in urban areas and minimize the environmental impact on a global scale by complying with emission regulations.

Efficient operation of emissions control systems not only contributes to cleaner air but also leads to improved fuel efficiency and reduced greenhouse gas emissions. This is essential for combating climate change and creating a sustainable future.

- Protecting human health.

These systems effectively reduce the release of toxic substances into the atmosphere, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). By curbing these pollutants, emission control systems prevent respiratory diseases, cardiovascular issues, and other health problems caused by poor air quality.

- Meeting environmental standards.

Compliance with emission regulations ensures that vehicles meet stringent standards set by governmental bodies. This helps in curbing pollution levels, especially in densely populated urban areas where vehicle emissions have a significant impact on air quality.

- Reducing greenhouse gas emissions.

Emission control systems contribute to mitigating climate change by minimizing the release of greenhouse gases like carbon dioxide (CO2) from vehicles.

The impact of emission control systems.

The impact of emission control systems is how they’ve revolutionized the way we tackle harmful pollutants in the atmosphere. By implementing these systems, we have witnessed a significant reduction in emission levels, resulting in numerous benefits for both our health and the environment.

1. Improved air quality.

Improved air quality is one of the most notable outcomes achieved through emission control systems. These systems effectively filter out harmful particles and gases emitted by automobiles, leading to cleaner and fresher air for all. As a result, respiratory diseases have decreased, and individuals can breathe easier knowing that their well-being is protected.

2. Combating climate change.

The continuous advancements in emission control technology are vital for further reducing vehicle emissions and combating climate change. Stricter emission regulations have pushed automobile manufacturers to develop more efficient systems that minimize the release of harmful substances into the atmosphere. This progress not only benefits us today but also safeguards future generations from the detrimental effects of pollution.

3. Efficiency and power.

Manufacturers strive to strike a balance between reducing emissions while maintaining optimal engine performance. Through innovative engineering, they have managed to achieve impressive results where emission reductions do not lead to significant power loss or compromises in vehicle efficiency.

How to clear a service emission system warning.

Clearing a service emission system warning may require diagnosing and addressing underlying issues that triggered the warning. It is important to take the necessary steps to resolve these problems in order to ensure optimal vehicle performance and reduce harmful emissions. Here are some key points to consider:

- Professional assistance.

To identify and resolve specific problems related to the service emission system, it is recommended to seek professional assistance from qualified mechanics or automotive technicians. These experts have the knowledge and experience to diagnose the issue accurately and provide appropriate solutions.

- Regular maintenance.

Regular maintenance plays a crucial role in preventing service emission system warnings. Timely replacement of faulty components can help avoid triggering these warnings, ensuring that your vehicle operates efficiently while minimizing environmental impact.

Tips for clearing service emission system warnings.

Checking for loose or damaged gas cap, inspecting oxygen sensors

1. Check for loose or damaged gas caps.

A loose or damaged gas cap can cause an emission system warning. Ensure that the gas cap is properly tightened or consider replacing it if necessary.

2. Inspect oxygen sensors.

Symptoms of faulty oxygen sensors include inaccurate readings and triggering service emission system warnings among others. Have them checked by a professional and replace any malfunctioning sensors.

3. Address catalytic converter issues.

A failing catalytic converter can result in increased emissions and trigger warnings. If diagnosed as a problem, consult with an expert on potential repair or replacement options.

Types of emissions: A comprehensive overview.

Carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), particulate matter (PM), and volatile organic compounds (VOCs) are the different types of emissions that we need to understand.

Each type has its own distinct sources, impacts on human health and the environment, as well as corresponding regulations for control.

- Carbon monoxide (CO).

This colorless and odorless gas is produced by the incomplete combustion of fossil fuels. It can be emitted from vehicles, industrial processes, and residential heating systems. High levels of CO can lead to headaches, dizziness, and even death in extreme cases.

- Nitrogen oxides (NOx).

These gases are formed when nitrogen reacts with oxygen during combustion processes. They are primarily released from vehicle engines and power plants. NOx emissions contribute to smog formation, respiratory issues, and acid rain.

- Hydrocarbons (HC).

HC emissions result from the incomplete combustion of fossil fuels or organic compounds. They come from sources like vehicle exhausts, industrial processes, and evaporation of gasoline. HC emissions play a significant role in the formation of ground-level ozone and contribute to respiratory problems.