The wheel and axle offers efficiency in its ability to distribute weight and reduce friction through the use of bearings. It is a simple machine designed to make work easier through the use of a wheel attached to an axle.

The wheel and axle enable us to move objects with greater ease by providing a fulcrum for rotational motion. The different types and sizes of wheel and axle have unique impacts on efficiency and performance.

Wheel and axle definition.

A wheel and axle is a mechanical device used to transmit rotational motion. It consists of a larger wheel connected to a smaller axle, allowing for the efficient movement of heavy loads.

- Mechanical device for transmitting rotational motion.

The primary function of a wheel and axle is to transfer rotational motion from one component to another. This makes it an essential tool in various applications, such as transportation, machinery, and simple machines.

- Consists of a larger wheel connected to a smaller axle.

The design of the wheel and axle involves a larger circular component (the wheel) connected to a narrower cylindrical shaft (the axle). The two components rotate together, with the force applied at the circumference of the wheel being transferred to the axle.

- Allows for efficient movement of heavy loads.

By utilizing leverage and mechanical advantage, the wheel and axle enable the efficient movement of heavy objects. When force is applied to the rim or edge of the wheel, it creates torque that causes rotation around the central axis provided by the axle. This design reduces friction compared to directly dragging or lifting heavy objects.

Wheel and axle examples.

Examples of wheel and axle systems are the bicycle wheels with axles at their centers, steering wheels connected to steering axles in cars and windmill blades rotating around central axles.

(a). Wheel and axle mechanism in bicycle.

Bicycle wheels are a classic example of the wheel and axle mechanism. The axle, which is a rod or shaft, runs through the center of the wheel. As the bicycle moves forward, the rotation of the wheel around its axle allows for smooth and efficient movement.

(b). Steering wheels in cars.

In cars, the steering wheel linkage connects the wheel to the steering axles. This connection enables drivers to control the direction of their vehicles. By turning the steering wheel, they manipulate the position of the front wheels and guide the car along desired paths.

(c). Wheel and axle system in windmills.

Windmills also utilize a wheel and axle system. The blades of windmills rotate around central axles when exposed to wind currents. This motion converts wind energy into mechanical energy, which can then be used for various purposes such as generating electricity or pumping water.

These examples demonstrate how the wheel and axle concept is applied in different contexts. Whether it’s in transportation systems like bicycles and cars or renewable energy solutions like windmills, this mechanism plays a crucial role in facilitating movement and harnessing natural forces.

Wheel and axle simple machine.

The wheel and axle mechanism makes work easier by either multiplying or changing the direction of force applied. It serves as the foundation for more complex machines, showcasing its significance in various domains.

The wheel and axle can be visualized as a device consisting of two parts: a large wheel and a smaller drum-like structure known as the axle. The wheel has a larger radius compared to the axle, enabling it to cover greater distances with each rotation.

Here are some examples of numerous practical applications that are made possible by harnessing the power of this simple machine.

- Hinges.

The wheel and axle concept is employed in hinges to enable smooth rotation.

- Windmills.

These structures utilize the power of wind to rotate large wheels, generating energy.

- Weightlifting devices.

Pulleys equipped with wheels and axles make it easier to lift heavy weights.

Wheel and axle uses.

The wheel and axle is a fundamental mechanical device commonly found in vehicles, machinery, and tools. It serves various purposes and enables a wide range of lifting, pulling, and transportation tasks.

- Common applications.

The wheel and axle can be seen in everyday objects such as cars, bicycles, carts, and wagons. These devices utilize the mechanical advantage provided by the wheel and axle to facilitate movement with less effort.

- Pulley systems.

The wheel and axle principle is employed in pulley systems to lift heavy loads. By incorporating multiple wheels with axles and ropes or cables, pulleys allow for efficient vertical displacement of objects.

- Gears.

Gears are another significant application of the wheel and axle mechanism. They consist of interlocking wheels with teeth that transmit rotational motion between shafts at different speeds or torques. Gears play a crucial role in various machines like engines, clocks, transmissions, and many more.

- Winches.

Winches utilize the wheel and axle setup to provide mechanical advantage for pulling tasks. These devices are commonly used in industries such as construction, maritime operations, off-roading activities, or even for recreational purposes like towing vehicles or boats.

How does a wheel and axle work?

The wheel and axle is a simple machine that enables the efficient transfer of energy or motion. It works by utilizing the principles of rotational force, leverage, and mechanical advantage.

- Rotational force applied at the wheel transfers to the axle.

When a force is exerted on the wheel, such as pushing it or applying torque, this force is transferred to the axle. The wheel and axle are connected in such a way that any rotation of the wheel causes an equal rotation of the axle.

- Leverage created by the difference in wheel and axle sizes amplifies force.

The key aspect of the wheel and axle mechanism lies in its design. The wheel has a larger radius compared to the smaller radius of the axle. This size difference creates leverage, allowing for an amplification of force applied to the wheel. As a result, even a small input force on the rim of the wheel can generate a larger output force at the end of the axle.

- Allows for efficient transfer of energy or motion.

By harnessing rotational force and leverage, the wheel and axle facilitate effective energy transfer. This makes it possible to perform various tasks with ease.

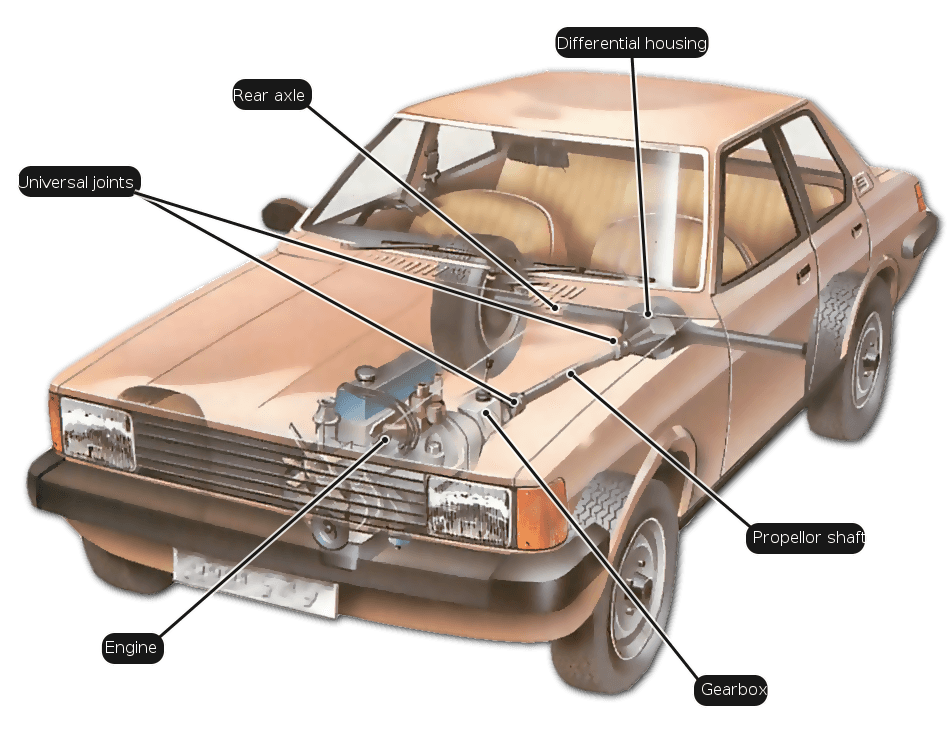

Wheel and axle in car.

The wheel and axle system is an essential component of a car’s drivetrain, enabling the transfer of power from the engine to the wheels for movement. Insufficient traction is one of the symptoms of a broken car axle.

The mechanism of a car wheel and axle ensures smooth rotation to allow the vehicle efficiently movement on various surfaces.

Car axle.

The axle, often referred to as a shaft, connects the wheels on either side of the car. It acts as a central support structure that allows the wheels to rotate freely while maintaining stability. The axle works in conjunction with gears within the car’s transmission system to control speed and torque distribution.

The wheel and axle work together to provide mechanical advantage in a wheeled vehicle. By using leverage, they amplify force applied by the engine or human power input. This mechanical advantage allows for easier movement and navigation.

Wheel and axle mechanical advantage.

Leverage gained through the difference in wheel-to-axle radius, reduction of the effort required, and the radii of the wheel and axle are some of the wheel and axle mechanical advantages.

The mechanical advantage of a wheel and axle system is determined by comparing the radii of the wheel and axle. This simple yet ingenious mechanism leverages the difference in radius to increase efficiency and reduce the effort required for various tasks.

- Leverage gained through the difference in wheel-to-axle radius.

The main principle behind the mechanical advantage of a wheel and axle lies in the varying radii between these two components. By having a larger radius on the wheel compared to that of the axle, a significant leverage is achieved. This leverage allows for easier movement or manipulation of objects connected to the system.

- Increases efficiency by reducing effort required.

When using a wheel and axle, the mechanical advantage obtained from its design reduces the amount of force needed to achieve a specific outcome. This increased efficiency enables individuals to perform tasks with less physical exertion, making it an invaluable tool across various industries.

- Ratio determines mechanical advantage.

The ratio between the radii of the wheel and axle directly influences the resulting mechanical advantage. A larger ratio translates into a greater leverage effect, providing an even more significant reduction in effort required. Engineers often calculate this ratio when designing systems involving wheels and axles to optimize their performance.

Different types of wheel and axle machines.

Clocks with gears driven by a central axle, pulleys using multiple wheels on common axles, and belt-driven machinery utilizing large drive wheels are the different types of wheel and axle machines.

- Clocks with gears driven by a central axle.

Clock mechanisms consist of various types of wheels and axles. Gears are commonly used to transfer motion from the central axle to the clock’s hands. The rotation of the wheel on the axle allows for precise timekeeping.

- Pulleys using multiple wheels on common axles.

Pulley systems often incorporate multiple wheels mounted on a shared axle. This arrangement enables mechanical advantage, allowing heavy loads to be lifted with less effort. By distributing the load across several wheels, pulleys can increase lifting capacity.

- Belt-driven machinery utilizing large drive wheels.

Belt-driven machines employ a system where a belt wraps around a large drive wheel connected to an axle. The rotation of the drive wheel transfers power through the belt, enabling various operations such as milling or cutting. This type of mechanism is commonly found in industrial settings.

Applying force to wheel machines and axle machines.

Human input, natural power sources, engines and motors are some of the methods of applying force to wheel machines and axle machines.

- Human input.

People exert force on wheel surfaces using their hands or feet.

This input force allows the wheels to move, overcoming friction.

- Engines and motors.

Machines equipped with engines or motors provide rotational force to axles.

The power generated by these engines enables the wheels and axles to turn.

- Natural power sources.

Wind, water, and animal power can also be harnessed to drive wheels and axles.

These forces are applied to the machines, transferring energy that moves the wheels.

Examples of applications.

wheelchairs, vehicles and industrial machinery are some of the examples of applications for the wheel and axel technology.

- Chairs.

When sitting on a chair with wheels, pushing off the ground with your feet applies force that propels the chair forward.

- Vehicles.

Engines in cars or motorcycles exert force on the axle, which rotates the wheels, enabling movement.

- Industrial machinery.

In manufacturing plants, various machines rely on wheel and axle systems for efficient operation.

Importance of applying force.

The application of force is crucial for initiating motion in wheel machines and axle machines. Without an input force, these systems would remain stationary.

Wheel and axle kits.

Components of the wheel and axle kits are useful for building wheel and axle machines. Some of the key features to consider when choosing a wheel and axle kit includes easy assembly and versatility.

These kits simplify the process of exploring the fascinating world of wheels and axles by offering ready-to-assemble sets with all the necessary components.

- Easy assembly.

The kits come with clear instructions and pre-cut parts, ensuring a straightforward setup process.

- Versatility.

Users can build various types of wheel and axle machines, such as pulley systems or toy cars, allowing for a wide range of applications.

- Hands-on exploration.

By constructing these machines from scratch, learners gain a deeper understanding of how the wheel and axle system functions.

- Practical learning.

These kits enable users to apply theoretical knowledge to practical situations, fostering problem-solving skills.

- Engaging activities.

Building wheel and axle machines offers an enjoyable way to learn about mechanical concepts while encouraging creativity.

Wheel and axle kits for carts.

The wheel and axle kits for carts typically consist of wheels, axles, brackets, and fasteners. With these components at your disposal, you won’t have to waste time searching for individual parts or worry about compatibility issues.

If you’re embarking on a cart construction project, wheel and axle kits designed specifically for this purpose will save you time and effort. These kits include all the essential components needed to create functional carts, ensuring a smooth and hassle-free construction process.

Everything is conveniently bundled together in one kit, allowing you to focus on building your cart without any unnecessary distractions. Ensure that your cart is equipped with high-quality wheels that are suitable for various terrains by using these kits.

Whether you need sturdy wheels for heavy loads or ones that offer enhanced maneuverability, there are different options available to suit your specific requirements.

Benefits of using wheel and axle kits for carts.

Convenience, compatibility, versatility and durability are some of the benefits of using wheel and axle kits for carts.

- Convenience.

All the necessary components are included in the kit, saving you time and effort in sourcing individual parts.

- Compatibility.

The components within the kit are designed to work seamlessly together, ensuring proper functionality.

- Versatility.

There are different types of kits available to accommodate various cart designs and purposes.

- Durability.

The components are made from durable materials that can withstand frequent use and rough conditions.

Wheel and axle parts.

The wheel hub, rim and axel form the major parts of the entire wheel and axle mechanism.

- Hub.

The hub is the center part of the wheel where the axle attaches. It serves as a crucial component that allows for the rotation of the wheel. The axle is securely fixed to the hub, providing stability and support.

- Rim.

The outer edge of the wheel is known as the rim. This is the part of the wheel that comes into contact with the ground. The rim plays a vital role in providing traction and maintaining balance while in motion. It also helps to distribute weight evenly across the wheel.

- Axle.

The axle is a rod or shaft that connects two wheels together. It acts as a central axis around which both wheels rotate simultaneously. By linking multiple wheels, it enables smooth movement and ensures synchronized motion.