The gasoline direct injection technology replaces traditional carburetors and it has been proven to improve both fuel efficiency and power output. Hence, offering drivers a more efficient and powerful driving experience.

According to recent studies, vehicles equipped with gasoline direct injection can achieve up to 15% better fuel economy compared to vehicles with conventional fuel delivery systems. This means fewer trips to the gas station and more money saved on fuel expenses.

This technology provides a significant boost in engine performance by delivering precise amounts of fuel directly into each cylinder, enhancing combustion efficiency.

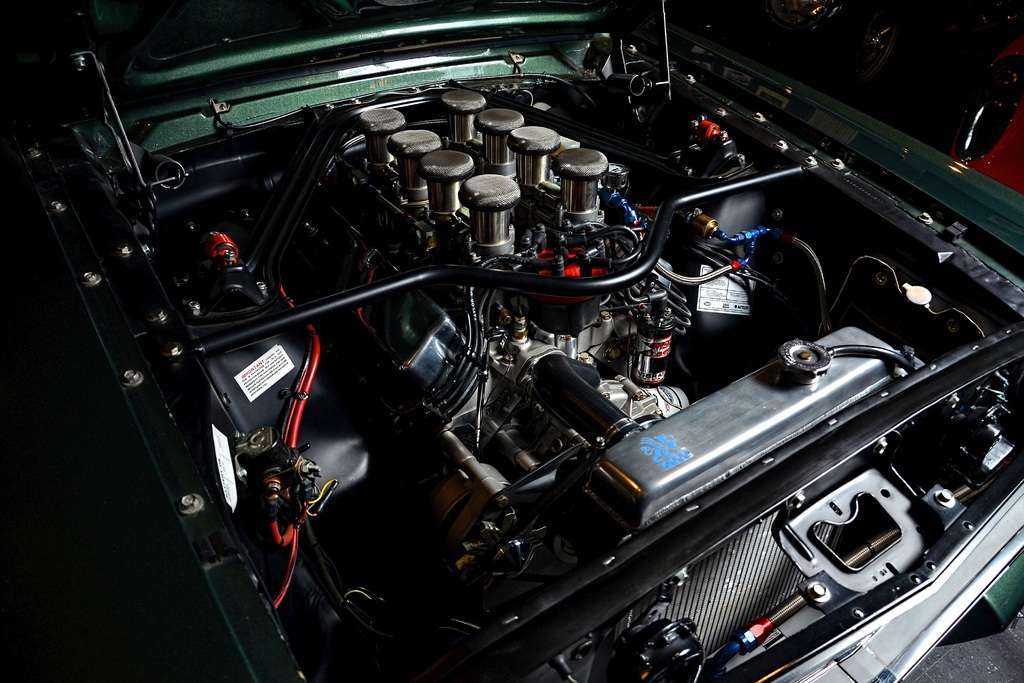

Direct injection system.

Gasoline direct injection, also known as a direct injection system, is a technology that delivers fuel directly into the combustion chamber of an engine. This vehicle fuel system offers precise control over fuel delivery, resulting in enhanced engine performance and reduced emissions.

With direct injection, fuel is injected directly into the combustion chamber through an injection nozzle or injector. Unlike traditional manifold injection systems where fuel is mixed with intake air before entering the cylinder, direct injection allows for more efficient and targeted fuel delivery.

One of the key advantages of a direct injection engine is its ability to optimize injection timing. By injecting fuel directly into the combustion chamber, technicians can fine-tune the timing to achieve optimal combustion efficiency. This leads to improved power output and better fuel economy.

Furthermore, direct injection systems enable engines to operate in different modes such as stratified charge mode. In this mode, a lean mixture near the spark plug ignites first while the rest of the air-fuel mixture remains relatively rich. This stratified charge improves combustion stability and reduces emissions.

Gasoline direct injection system.

The gasoline direct injection (GDI) system is a crucial component in modern gasoline engines. It sprays fuel at high pressure directly into the combustion chamber of the cylinder, optimizing the air-fuel mixture for efficient combustion.

By delivering fuel directly into the combustion chamber, the GDI system ensures precise control over the fuel injection process. This allows for a more accurate and efficient distribution of fuel, resulting in improved power and torque output from the engine.

One of the key advantages of gasoline direct injection is its ability to reduce fuel consumption. By precisely controlling the amount and timing of fuel injected into the cylinder, GDI systems can achieve better fuel efficiency compared to traditional port fuel injection systems.

Gasoline direct injection helps minimize carbon deposits within the combustion chamber. The high-pressure spray of fuel helps clean away any build-up, leading to improved engine performance and longevity.

Automotive service technicians and mechanics play a vital role in maintaining and servicing GDI systems. They need to ensure that fuel injectors are clean and functioning properly to maintain optimal performance.

Different types of gasoline direct injection.

The main types of fuel injection systems are single-point injection system and multi-point injection system.

Gasoline direct injection (GDI) systems come in various types, with each one offering unique advantages and characteristics.

1. Single-point injection system.

The single-point injection system is a straightforward approach to GDI. It involves injecting fuel directly into the intake manifold or cylinder head through a single injector. This type of system is commonly found in older vehicles and offers simplicity and cost-effectiveness.

2. Multi-point injection system.

Unlike the single-point system, the multi-point injection (MPI) system utilizes multiple injectors strategically placed near each intake valve. This allows for more precise fuel distribution among cylinders, resulting in improved engine performance and fuel efficiency. MPI systems are commonly found in modern vehicles.

3. Stratified charge injection system.

The stratified charge injection (SCI) system takes GDI to another level by optimizing fuel-air mixture within the combustion chamber. It uses a combination of direct and indirect injections to create a stratified charge, where the air-fuel mixture near the spark plug is richer than at other locations. This enhances combustion efficiency, leading to better fuel economy and reduced emissions.

Diesel direct injection.

Fuel injected directly into the diesel engine’s combustion chamber, diesel direct injection achieves better fuel atomization and combustion efficiency compared to indirect injection. This technology is commonly used in modern diesel engines due to its numerous benefits.

Direct fuel injection in diesel engines involves the precise delivery of fuel into the combustion chamber through a fuel injector. Unlike indirect injection, which sprays fuel into a pre-combustion chamber, this method allows for more efficient combustion and improved power output.

One advantage of diesel direct injection is its impact on exhaust emissions. By injecting fuel directly into the combustion chamber, it promotes cleaner burning and reduces harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM). This makes it an ideal choice for meeting stringent emission standards imposed on various industries, including automotive and aircraft engines.

Moreover, this technology enhances overall engine performance. The precise control over the amount and timing of fuel injected allows for optimal combustion, resulting in increased power and torque. Direct injection contributes to improved fuel efficiency by ensuring that every drop of fuel is utilized effectively.

Diesel direct injection also offers advantages in terms of maintenance and longevity. It helps prevent carbon buildup on intake valves by avoiding contact with oil present in the air intake system. This reduces the need for frequent cleaning or valve maintenance, saving both time and money for diesel engine specialists or truck mechanics.

Direct injection vs indirect injection.

Direct injection and indirect injection are two different methods of delivering fuel to the combustion chamber in an internal combustion engine.

In direct injection, fuel is injected directly into the combustion chamber. On the other hand, in indirect injection, fuel enters through a pre-combustion chamber or intake port before reaching the combustion chamber.

One advantage of direct injection is that it provides better control over the air-fuel mixture. By injecting fuel directly into the combustion chamber, it allows for more precise timing and distribution of fuel, resulting in improved efficiency and performance.

Direct injection offers several benefits compared to indirect injection. It helps in achieving higher power output, increased torque, and improved fuel economy. It reduces emissions by enabling more efficient combustion.

Advantages of indirect injection.

Indirect injection offers several advantages over direct-injection systems. Let’s take a closer look at these benefits:

- Less expensive to manufacture.

Indirect injection systems are more cost-effective to produce compared to their direct-injection counterparts. This affordability makes them an attractive option for many manufacturers.

- Simpler design with fewer components.

Indirect injection systems have a simpler design, consisting of fewer components. This simplicity not only reduces manufacturing costs but also enhances reliability and durability.

- Easier maintenance due to less complexity.

With fewer components and a simpler design, indirect injection systems are easier to maintain. Mechanics find it less challenging to diagnose and repair issues, resulting in shorter downtime for vehicle owners.

Disadvantages of indirect injection.

Indirect injection systems have some notable drawbacks when compared to their direct-injection counterparts like lower overall efficiency compared to direct-injection systems, poorer atomization of fuel leading to incomplete combustion and higher emissions due to inefficient burning of fuel.

- Lower overall efficiency.

One significant disadvantage is their lower overall efficiency. Unlike direct injection, which injects fuel directly into the combustion chamber, indirect injection involves injecting fuel into a pre-combustion chamber or intake manifold. This indirect method results in a less efficient combustion process, leading to decreased fuel economy.

- Poorer atomization of fuel.

Another drawback of indirect injection is the poorer atomization of fuel. In this type of system, the fuel is not finely misted before entering the combustion chamber. As a result, the fuel droplets are larger and less uniformly distributed, which can lead to incomplete combustion. This incomplete combustion contributes to reduced power output and increased emissions.

- Produce higher levels of pollutants.

Speaking of emissions, indirect injection systems tend to produce higher levels of pollutants compared to direct-injection systems. The inefficient burning of fuel in an indirect injection setup leads to an increase in unburned hydrocarbons and other harmful exhaust gases being released into the environment.

Pros of direct injection engines.

Direct injection engines offer several advantages over conventional engines like increased power output and torque, better fuel economy and lower emissions.

- Increased power output and torque.

One of the major advantages of gasoline direct injection engines is their ability to deliver higher power output and torque compared to traditional engines. By injecting fuel directly into the combustion chamber, these engines optimize the air-fuel mixture, resulting in improved combustion efficiency and enhanced performance.

- Better fuel economy.

Direct injection engines excel at optimizing the air-fuel ratio, leading to better fuel economy. By precisely controlling the amount of fuel injected into each cylinder, these engines ensure that only the necessary amount is used for combustion, reducing wastage and maximizing efficiency.

- Lower emissions.

Another significant advantage of direct injection engines is their ability to reduce emissions. The precise control over the fuel injection process allows for more complete combustion, resulting in lower levels of harmful pollutants being released into the environment. This improved combustion efficiency contributes to a greener and more sustainable driving experience.

Disadvantages of direct injection.

Some of the disadvantages of direct injection are carbon buildup on intake valves can occur over time, higher manufacturing costs due to complex fuel delivery systems and requires higher fuel pressure for injection.

- Carbon buildup on intake valves can occur over time.

Direct injection has its drawbacks, and it’s important to be aware of them before making a decision. One significant disadvantage is the potential for carbon buildup on intake valves over time. This occurs because direct injection bypasses the usual cleaning action of fuel flowing over the valves, leading to a gradual accumulation of carbon deposits. As a result, engine performance may suffer, and additional maintenance may be required to address this issue.

- Higher manufacturing costs due to complex fuel delivery systems.

Another drawback is the higher manufacturing costs associated with direct injection. Compared to traditional fuel delivery systems, direct injection requires more complex components and technology. These advancements raise production expenses, which can ultimately impact the overall cost of vehicles equipped with this technology.

- Requires higher fuel pressure for injection.

Furthermore, direct injection necessitates higher fuel pressure for efficient injection into the combustion chamber. The increased pressure ensures proper atomization and distribution of fuel within the cylinder. However, this requirement adds complexity to the system and may lead to increased wear on certain components over time.

While direct injection offers benefits such as improved power output and fuel efficiency, it’s essential to consider these disadvantages as well.

Common misconceptions about gasoline direct injection.

Some of the misconceptions are in the areas of engine noise, performance limitations and carbon buildup.

- Engine noise.

Contrary to popular belief, direct injection does not necessarily cause more engine noise. While it is true that some older direct injection engines may produce more noise, advancements in technology have significantly reduced this issue. Modern direct injection systems utilize improved fuel injectors and engine management software to minimize engine noise. Therefore, it is important to understand that the level of engine noise can vary depending on the specific design and implementation of the direct injection system.

- Performance limitations.

Another common misconception is that gasoline direct injection is only suitable for high-performance vehicles. However, this is far from the truth. While direct injection was initially adopted in high-performance engines due to its ability to enhance power and efficiency, it has now become a widely used technology across various vehicle types. Many mainstream vehicles now feature direct injection as manufacturers strive to meet stricter fuel efficiency regulations. This technology offers benefits such as improved fuel economy and reduced emissions, making it suitable for both performance-oriented cars and everyday commuter vehicles.

- Carbon buildup.

It is often believed that direct injection engines are prone to carbon buildup. While there is some truth to this claim, modern advancements have mitigated this issue as well. Carbon buildup occurs when fuel additives fail to clean intake valves effectively due to the absence of fuel spraying onto them directly.

Power and efficiency of gasoline direct injection.

Gasoline direct injection (GDI) offers significant improvements in both power and efficiency compared to traditional engines. This advanced fuel delivery system enhances the overall performance of an engine, providing a range of benefits.

Gasoline direct injection problems.

Gasoline direct injection (GDI) has become increasingly popular in modern engines due to its efficiency and performance benefits. However, like any technology, GDI is not without its problems. Here are some common issues associated with gasoline direct injection:

- Carbon deposits on intake valves leading to reduced performance.

One of the main challenges with GDI is carbon buildup on the intake valves. Unlike traditional port fuel injection systems, GDI injects fuel directly into the combustion chamber, bypassing the intake valves. This can result in a lack of fuel washing over the valves, leading to carbon deposits over time. These deposits can restrict airflow and affect engine performance.

- Potential fuel pump failures due to increased pressure requirements.

Gasoline direct injection systems require higher fuel pressures compared to conventional fuel injection systems. This increased pressure puts additional strain on the fuel pump, increasing the risk of failure. If the fuel pump malfunctions or fails, it can lead to engine stalling or poor performance.

- Fuel injector clogging or malfunctioning affecting combustion efficiency.

Another problem associated with GDI is the potential for fuel injector clogging or malfunctioning. The precise spray pattern and timing of the fuel injectors are crucial for optimal combustion efficiency.