Exhaust Gas Recirculation (EGR) technology is how vehicle emissions can be reduced to meet strict emission standards. EGR helps lower combustion temperatures and reduces the formation of harmful pollutants, particularly nitrogen oxides (NOx).

Exhaust gas recirculation works by redirecting a portion of exhaust gases back into the engine’s combustion chamber. This technique plays a crucial role in reducing nitrogen oxide emissions, ensuring compliance with stringent emission standards like Euro VI or HR NOx.

Basics of EGR systems.

EGR systems play a crucial role in optimizing engine performance and reducing emissions. These systems consist of various components, including valves, coolers, and sensors. EGR systems contribute to a more efficient combustion process by regulating and controlling the flow of exhaust gases into the intake manifold.

The valves in an EGR system are responsible for controlling the flow of exhaust gases. They open and close to allow a certain amount of recirculated exhaust gas into the intake manifold.

a). Coolers.

Coolers are another important component of EGR systems. They help lower the temperature of the recirculated exhaust gas before it enters the intake manifold. This helps prevent excessive heat buildup and potential damage to engine components.

b). Sensors found in exhaust gas recirculation.

Sensors are used to monitor various parameters such as engine load and temperature. Based on these readings, the EGR system adjusts the amount of recirculated exhaust gas accordingly.

c). Engine load and temperature.

The amount of recirculated exhaust gas is determined by factors like engine load and temperature. During low-load conditions, less exhaust gas is recirculated, while higher loads may require increased recirculation for optimal performance.

Understanding the basics of EGR systems is essential for proper maintenance and troubleshooting. If any component malfunctions or becomes clogged with carbon deposits over time, it will affect engine performance and increase emissions.

Exploring different types of EGR systems.

External (high-pressure) and internal (low-pressure) EGR systems are the two main types of exhaust gas recirculation (EGR) systems. EGR valves are an essential component of the exhaust gas recirculation (EGR) system.

a). External EGR systems.

External EGR systems utilize a separate pipe to redirect exhaust gases from the manifold to the intake. Reducing nitrogen oxide emissions by diluting the air-fuel mixture with recirculated exhaust gases is one of the advantages offered by this type of EGR system.

Secondly, its ability to lower combustion temperatures helps prevent engine knocking. Thirdly, it is capable of reducing pumping losses which enhances fuel efficiency.

However, external EGR systems also have their drawbacks. For instance, they can lead to increased soot accumulation in the intake manifold and require additional components like coolers to manage temperature levels effectively.

b). Internal EGR systems.

On the other hand, internal EGR systems recirculate gases directly within the engine through specially designed passages. The recirculated gases are reintroduced into the combustion chamber during specific engine cycles.

Internal EGR allows for precise control over the amount of recirculated gas, providing flexibility for optimizing performance and emissions. It eliminates the need for additional pipes and coolers associated with external EGR systems.

c).Cooled exhaust gas recirculation (EGR).

Some engines incorporate cooled EGR by passing the recirculated exhaust gases through a heat exchanger to lower their temperature before mixing with fresh air/fuel mixture.

d). Low-pressure exhaust gas recirculation (LP-EGR).

LP-EGR systems utilize low-pressure points within the engine to redirect and recirculate exhaust gases. It is an emissions control technology used in internal combustion engines, particularly in diesel engines.

It involves recirculating a portion of the exhaust gases back into the engine’s intake system, but at a lower pressure and temperature compared to traditional EGR systems.

e). High-pressure exhaust gas recirculation (HP-EGR).

HP-EGR systems route high-pressure exhaust gases back to the intake after-treatment system for further processing. The concept behind HP-EGR is to reintroduce a portion of the exhaust gases back into the engine’s intake manifold, which lowers the combustion temperature and thus reduces the formation of NOx during the combustion process.

While internal EGR systems offer benefits such as improved fuel economy and reduced emissions, they may require more complex engine designs and advanced control strategies.

How does EGR work in engines?

You need to look at recirculation of exhaust gases, mixing with intake air, combustion process, EGR valve control and lowering combustion temperatures in order to understand how does EGR work in engines.

In an internal combustion engine, a small portion of exhaust gas is mixed with fresh air/fuel mixture before entering the cylinders. This dilutes oxygen concentration, lowers peak combustion temperatures, and reduces NOx formation during combustion.

The recirculated exhaust gas displaces some combustible mixture but improves overall efficiency by reducing heat loss during the expansion stroke. Engines can adjust the amount of recirculated exhaust gas based on operating conditions by controlling valve timing or position.

a). Recirculation of exhaust gases.

A portion of the exhaust gases produced during combustion is redirected from the exhaust manifold back into the engine’s intake manifold. This process is managed by the EGR valve, which controls the amount of exhaust gas that is recirculated.

b). Mixing with intake air.

The recirculated exhaust gases mix with fresh air (and fuel, in the case of gasoline engines) before entering the engine’s combustion chambers. The mixture has a lower oxygen content than pure fresh air.

c). Lowering combustion temperatures.

The introduction of exhaust gases, which are inert (do not burn), into the air-fuel mixture dilutes the oxygen concentration. This dilution reduces the peak combustion temperature inside the cylinders.

Lower combustion temperatures reduce the thermal formation of nitrogen oxides (NOx), which primarily form at high temperatures (above 2,500°F or 1,370°C).

d). Combustion process.

With the EGR system active, the engine operates at a cooler temperature, which slows down the combustion process. This results in reduced NOx emissions.

e). EGR valve control.

The EGR valve is the key component in the system. It opens and closes based on engine operating conditions such as load, speed, and temperature.

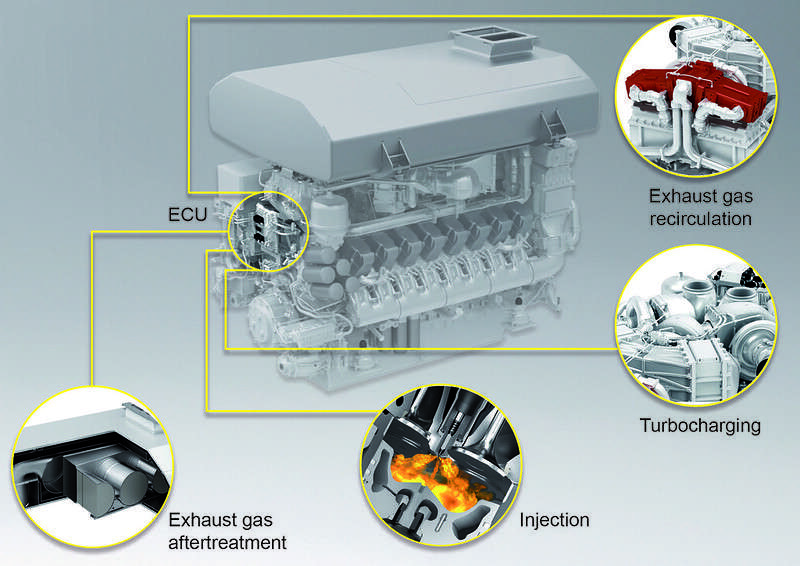

Modern engines use electronically controlled EGR valves that are regulated by the engine control unit (ECU). The ECU adjusts the EGR valve’s position to optimize the amount of exhaust gas recirculated, ensuring efficient engine performance while minimizing emissions.

Adjusting valve timing or position allows precise control over how much recirculated exhaust gas enters the cylinders.

Benefits of exhaust gas recirculation (EGR).

Improving fuel efficiency, lowering peak combustion temperatures and meeting stringent emission regulations are some of the benefits of the exhaust gas recirculation system.

Reducing nitrogen oxide (NOx) emissions is a significant advantage of implementing effective exhaust gas recirculation (EGR). By diverting a portion of the exhaust gases back into the combustion chamber, EGR helps lower NOx levels, contributing to cleaner air quality.

- Improving fuel efficiency.

Reduction of vehicle fuel consumption is another benefit of EGR. By recirculating exhaust gases, the need for excess fuel to control combustion temperatures is reduced. This not only saves on fuel costs but also promotes better environmental sustainability by lowering carbon dioxide emissions.

- Lowering peak combustion temperatures.

Lowering peak combustion temperatures through EGR can have positive effects on engine durability. By reducing heat stress on components, such as valves and pistons, EGR can extend engine life and minimize wear and tear.

- Meeting stringent emission regulations.

The use of EGR systems enables manufacturers to meet stringent emission regulations without compromising performance. By effectively managing NOx emissions while maintaining engine power and responsiveness, vehicles equipped with EGR valves can provide both eco-friendly operation and satisfying driving experiences.

Significance of exhaust gas recirculation.

The significance of the Exhaust gas recirculation (EGR) system is to strike a balance between performance, fuel efficiency, and environmental impact.

Another significance of the exhaust gas recirculation system is that it is crucial for meeting emission standards. Whereby it reduces harmful pollutants while maintaining engine power output.

- Compliance with emission standards.

EGR plays a vital role in achieving compliance with emission standards set by regulatory bodies worldwide. This technology allows engines to meet the stringent requirements imposed by these regulations. Without EGR, vehicles would struggle to adhere to the limits on harmful emissions.

- Reduce nitrogen oxide (NOx) emissions.

By recirculating a portion of exhaust gases back into the combustion chamber, EGR helps reduce nitrogen oxide (NOx) emissions. Nitrogen oxides are major contributors to air pollution and have detrimental effects on human health and the environment. EGR effectively tackles this issue by lowering the combustion temperature and limiting the formation of NOx.

- Improved fuel efficiency.

In addition to its environmental benefits, EGR also contributes to improved fuel efficiency. By reintroducing exhaust gases into the combustion process, less fuel is required for complete combustion. This leads to better mileage and reduced carbon dioxide (CO2) emissions.

As emissions regulations continue to evolve, effective exhaust gas recirculation becomes even more important. Stricter standards necessitate advanced technologies like EGR to ensure compliance without compromising engine performance or fuel economy.

Exhaust gas recirculation sensor.

The exhaust gas recirculation (EGR) sensor is responsible for monitoring various parameters related to exhaust gas recirculation. This sensor plays a crucial role in ensuring the proper functioning of the system by measuring factors such as temperature, pressure, and flow rate.

By providing real-time data, the EGR sensor helps optimize engine performance and diagnose potential issues or malfunctions. It serves as a valuable tool for automotive repair professionals in identifying problems with the EGR system.

A faulty or malfunctioning EGR sensor can have detrimental effects on engine operation and emissions. Here are some key points to consider:

The EGR sensor works in conjunction with other components like temperature sensors, pressure transducers, vacuum connections, and poppet valves. It measures the temperature of exhaust gases to determine if they are within acceptable ranges for recirculation.

- Pressure transducers.

Pressure transducers assist in monitoring the pressure levels within the system.

- Flow rate measurements.

Flow rate measurements help ensure that an appropriate amount of exhaust gas is being recirculated.

The EGR sensor also plays a role in controlling air excess ratio and managing diesel particulate filter regeneration processes.

Exhaust gas recirculation control circuit.

The exhaust gas recirculation (EGR) control circuit regulates the opening and closing of the EGR valve. This circuit takes input from various sensors to ensure precise control over the amount of recirculated exhaust gas under different operating conditions.

A properly functioning control circuit is essential for maintaining optimal engine performance and keeping emission levels within acceptable limits. However, malfunctions in this circuit can lead to drivability issues, increased emissions, or even potential engine damage.

- Overseeing the operation of the EGR valve.

The control unit is responsible for overseeing the operation of the EGR valve. It receives information from sensors such as the exhaust gas temperature sensor, throttle position sensor, and manifold absolute pressure sensor.

Based on this input, the control unit determines when to open or close the EGR valve. By adjusting the valve’s position, it regulates how much exhaust gas is redirected back into the combustion chamber.

- Monitoring feedback from sensors.

The control circuit operates in a closed-loop system, continuously monitoring feedback from sensors to maintain optimal performance. If any anomalies are detected, it can trigger diagnostic trouble codes (DTCs) indicating potential issues with the EGR system.

An intermittent fault in the control circuit may cause sporadic problems with EGR operation. This could result in fluctuating engine performance or irregular emission levels.

In some cases, a malfunctioning control position sensor within the circuit can cause erroneous readings and improper regulation of exhaust gas flow. This can lead to inefficient combustion and increased emissions.

Exhaust gas recirculation flow.

Exhaust gas recirculation (EGR) flow refers to the volume or rate at which exhaust gases are redirected back into the intake manifold during EGR operation. This process plays a crucial role in reducing NOx emissions without negatively impacting engine performance.

Proper control of the flow is essential to achieve desired emission reductions while maintaining optimal engine operation. Flow rates in the exhaust gas recirculation system can vary depending on factors such as engine load, temperature, and speed.

Monitoring and controlling the EGR flow rate are critical for ensuring emission compliance and maximizing engine efficiency.

- Flow control.

Proper flow control is necessary to achieve desired reductions in NOx emissions without adversely affecting other aspects of engine operation.

- Factors affecting flow rates.

Flow rates can vary based on factors such as engine load, temperature, and speed.

- Importance of monitoring.

Monitoring and controlling EGR flow is critical for maintaining emission compliance and optimal engine performance.

- Balancing emissions and performance.

The right balance between exhaust gas recirculation and fresh air intake ensures efficient combustion in the combustion chamber, reducing both NOx emissions and fuel consumption.

- Impact on intake system.

The EGR valve regulates the amount of exhaust gas flowing back into the intake system. It helps prevent excessive carbon buildup in the intake manifold and maintains proper air-fuel ratios.

- Reduction of harmful gases.

By redirecting a portion of exhaust gases back into the combustion chamber, EGR reduces peak combustion temperatures, minimizing the formation of nitrogen oxides (NOx).

Exhaust gas recirculation flow insufficient detected.

An error code or diagnostic trouble code (DTC) that indicates a problem with the flow rate can be concerning. This specific code suggests that the actual flow of recirculated exhaust gas is lower than expected or required by the engine control module.

Possible causes for this issue include clogged passages, malfunctioning valves, sensor issues, or leaks in the EGR system. These factors can result in insufficient exhaust gas recirculation flow and may lead to drivability problems, increased emissions, or potential damage to the engine if left unresolved.

Diagnose and resolve exhaust gas recirculation flow insufficient.

Inspect for clogged passages then inspect for clogged passages, check sensors and finally address leaks in order to diagnose and resolve exhaust gas recirculation flow insufficient.

- Inspect for clogged passages.

Check for any obstructions within the EGR system’s passages that could impede the flow of exhaust gas.

- Evaluate valve functionality.

Ensure that the EGR valve is operating correctly and opening/closing as needed.

- Check sensors.

Verify that all relevant sensors associated with the EGR system are functioning properly and providing accurate readings.

- Address leaks.

Identify and address any leaks within the EGR system to prevent loss of pressure or improper recirculation.

Rectify the insufficient exhaust gas recirculation flow issue effectively by addressing these potential causes of emission system problems and taking appropriate measures.

Common EGR problems.

Carbon buildup in EGR passages or valves, malfunctioning sensors, leaks and failure of the EGR system components are some of the common EGR problems. There are common instances that can cause problems with its functionality.

These issues can lead to reduced performance, increased emissions, and potential drivability concerns. Let’s take a closer look at some of these common EGR problems:

- Carbon buildup.

Over time, carbon deposits can accumulate in the EGR passages or valves. This buildup restricts the flow of exhaust gases, affecting the proper operation of the system. It can lead to decreased engine performance and even stalling.

- Malfunctioning sensors.

The EGR system relies on various sensors to provide data to the engine control module (ECM). If these sensors malfunction or provide inaccurate readings, it can result in improper EGR control. This may lead to an imbalance in air-fuel mixture and affect overall engine performance.

- Leaks.

Leaks within the EGR system can occur due to damaged gaskets or faulty connections. These leaks disrupt the proper flow of exhaust gases, reducing efficiency and increasing emissions. They need to be identified and repaired promptly for optimal vehicle performance.